MATRIX overview

MATRIX has been the product specialist for the "true-to-contour molding of complicated workpieces" since 1997. Anyone looking to achieve fast results in prototype construction or in preproduction runs, prefers a fast, flexible and easy-to-operate clamping system for complicated workpieces. Today many professionals worldwide opt for the patented clamping technology developed by MATRIX.

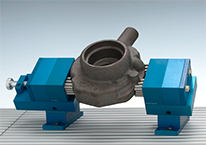

MATRIX's amazingly simple solution reduces time and costs. Like a pin-cushion, the pins of the MATRIX products adjust individually to the contours of the workpiece, no matter how complicated. The original workpiece has in this way created a completely true-to-shape clamping jaw. This mold is now fixed mechanically. The part-specific and sturdy mold is finished. Work that previously required laborious milling or molded supports, can now be completed in just a few seconds. Whereas conventional supports could only be used for a single workpiece, the MATRIX pin system can adjust to any workpiece contour.

Modular systems have developed around these innovative elements and are now established on the market. MATRIX is successful as a niche supplier and product specialist in the area of true-to-contour molds of complicated workpieces in production. The integrated cleaning of the pin systems makes maintenance easy and ensures reliable operation.

MATRIX User Base

MATRIX clamping technologies are used as jig systems in assembly, production, measurement and laboratory engineering, as well as in automation. A worldwide customer base includes companies in the fields of aviation, automotive, mechanical engineering, medical engineering and other high-tech sectors.